Our studies focused on testing of a passive nutrient and water delivery system using rooting pillows designed for direct contact with the Veggie root mat reservoir ( Stutte et al., 2011a). For salad crops growing for relatively short durations, however, passive nutrient delivery can be sufficient. Passive systems, like capillary wicking, have low energy requirements, but less control of delivery under variable environmental conditions, and can only function for limited durations until nutrients are exhausted. Active nutrient delivery provides the capability for extended cultivation scenarios by continual replenishment of water and nutrients ( Goins et al., 1997), but this increased control comes with increased energy and infrastructure requirements. A number of approaches for water/nutrient delivery have been tested for space, including porous membranes, either using constant pressure or ebb/flow delivery ( Wright et al., 1988 Koontz et al., 1990 Berkovich et al., 2002), porous tubes ( Morrow et al., 1992 Dreschel et al., 1994), contained, vacuum operated systems ( Brown et al., 1992), natural and manufactured solid substrates with sub-irrigation ( Bingham et al., 1996 Goins et al., 1997), and capillary wicking from a reservoir ( Kliss et al., 2000 Morrow et al., 2005 Morrow and Remiker, 2009).

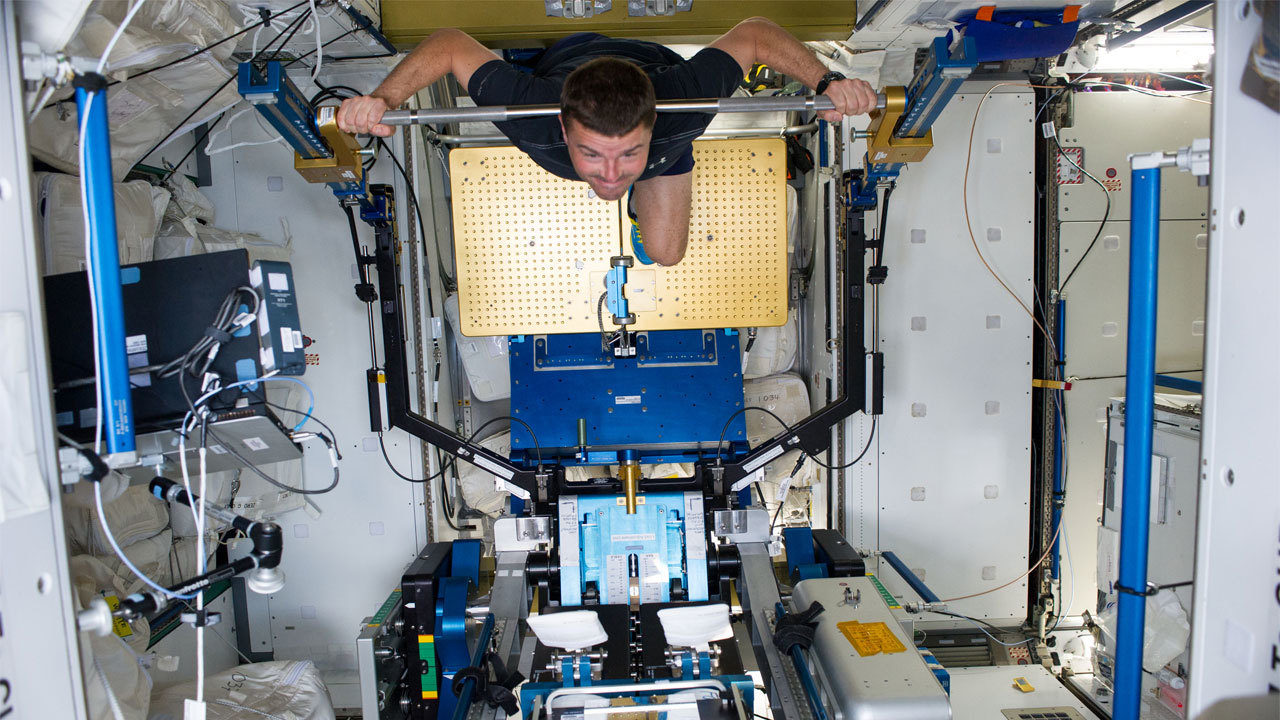

But a microgravity environment poses additional challenges for crop production, including maintenance of adequate nutrient and water delivery to the roots, without anoxia or salt-stress ( Porterfield, 2002). Veggie is currently considered one of the most advanced salad-machine precursors available ( Stutte et al., 2009) and has passed a NASA safety review for a planned delivery and test on the International Space Station (ISS) in early 2014.įor several years, researchers at ORBITEC ( Morrow and Remiker, 2009) and Kennedy Space Center ( Stutte et al., 2009 Stutte et al., 2011a, 2011b) have assessed the Veggie unit for baseline salad performance under 1 g. A Veggie unit consists of three main subsystems: an LED light cap, a bellows enclosure for the shoot environment, and a 0.14 m 2 root mat fed by a reservoir ( Morrow et al., 2005 and design revisions since). Salad crops recommended for space-life support scenarios that might be grown in a vegetable production unit such as Veggie include greens such as lettuce, spinach, chard, and mizuna, tomato, pepper, green onion, radish, herbs and strawberry ( Wheeler, 2009). The “Veggie” deployable salad-crop-production system, developed by the Orbital Technologies Corporation (ORBITEC, Madison, WI), is a modular, low mass, low energy unit with the versatility to grow a variety of crops in transit vehicles, space stations, or planetary habitat environments ( Morrow et al., 2005 Morrow and Remiker, 2009 Stutte et al., 2011b). As a first step, a “salad machine” or vegetable production unit will serve as a technology demonstration with the potential to produce fresh food to augment a packaged diet, remove CO 2, and generate O 2 to supplement cabin air, as well as provide psychological benefits for the crew ( Kliss and MacElroy, 1990).

Plants will play a critical role in these systems, both for food production and atmosphere regeneration ( Wheeler et al., 2001). As we approach long-term, off-Earth human exploration, mass and volume limitations will drive the need for sustainable closed-loop life-support systems.

0 kommentar(er)

0 kommentar(er)